February 2, 2012

Why is Plate Meshing Important?

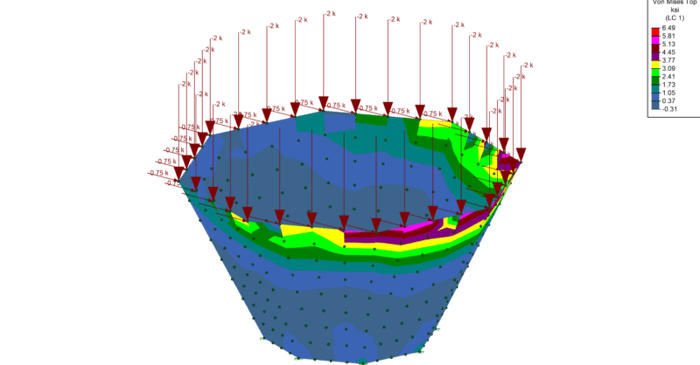

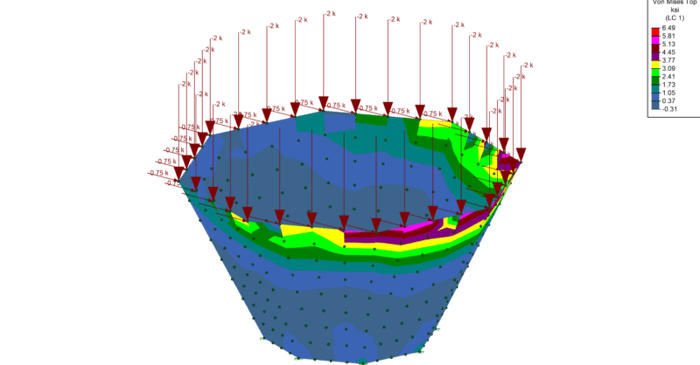

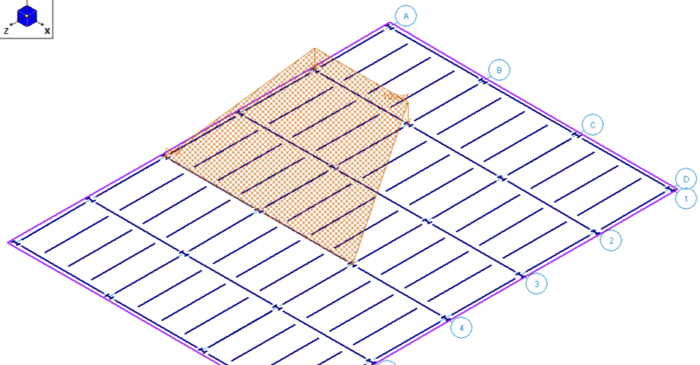

Aside from the topic of plate connectivity, the concept of plate meshing is equally important to the analysis of structures using finite elements (plates).

Powerful Tools Don’t Help If They’re Left Unused Many engineers evaluate analysis software based on core modeling and design checks. But once a demo is over, some of the most impactful features are the ones that quietly save time on real projects — especially mid-size jobs where efficiency matters most. These aren’t advanced edge-case tools. They’re everyday features that often go underused. Diaphragm Forces: See Load Paths Instead of Guessing Diaphragm force output is one of the most valuable — and least leveraged — parts of a full building model. Instead of relying on manual distribution or conservative assumptions, engineers can directly see how loads are flowing to vertical elements. For mid-size structures, this clarity can mean: Fewer overdesigned collectors More confidence in lateral load paths Faster review and revisions when layouts change Batch Results: Review Smarter, Not Longer Batch results allow engineers to review multiple load cases, members, or design checks in a single pass. Instead of hunting through individual reports, patterns become obvious quickly. On mid-size jobs, this speeds up: QA/QC reviews Iterative design changes Comparing “before and after” scenarios It’s not about skipping checks — it’s about seeing the full picture sooner. Design Iteration Speed Is the…

Read More

Aside from the topic of plate connectivity, the concept of plate meshing is equally important to the analysis of structures using finite elements (plates).

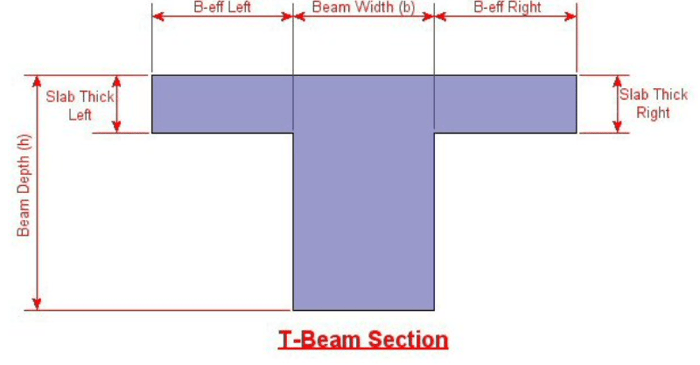

Modeling T-beams and L-beams in RISA-3D can easily be done by specifying the flanges after drawing in the rectangular concrete beam. The flange properties can be specified for individual members on the Concrete Beam tab of the Members spreadsheet, or for a group of selected members in the...

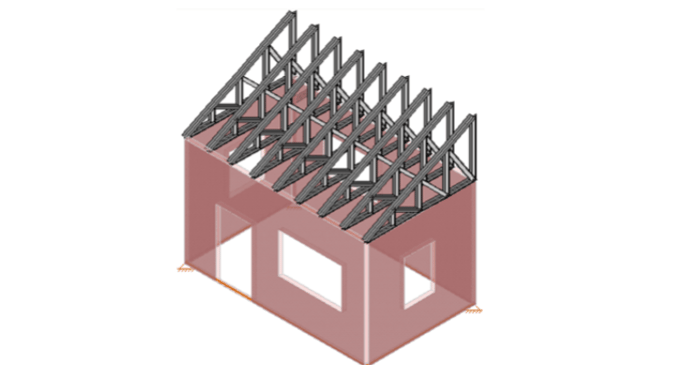

If you want to assign joists in a framing bay with an exact spacing RISAFloor will allow you to specify which side of the bay you want the program to start the spacing measurement from. Go to the Generate Beams within Bay option from the Drawing toolbar. Select the Exact Spacing of option in the...

RISA-3D allows you to append, or merge, multiple models into a single model file. This may be helpful if you model single floors in separate files and want to stack them together.

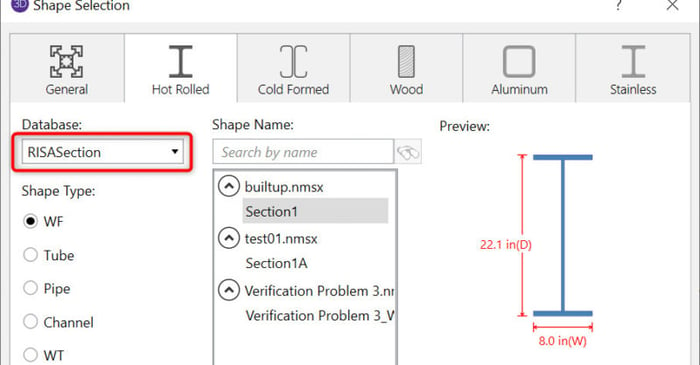

RISASection 2.0 includes the ability to assign your section as one of the predefined hot rolled steel Shape Types (Wide Flange, Channel, Tube, etc.). This means that when the shape is imported into RISA-3D, you will now be able to get design results and code checks for the member.

RISAFloor has the ability to apply tapered snow loads on your building’s roof to simulate drift snow loads.

RISAFloor uses the Area Load Definitions spreadsheet to define area loads available for use on a floor.

One of the most overlooked design criteria for commercial buildings is the tendency of the floor system to bounce or vibrate due to human footfalls. Excessive vibration of the floor system is a serviceability issue, and can lead to annoyance or concern from the building’s occupants.

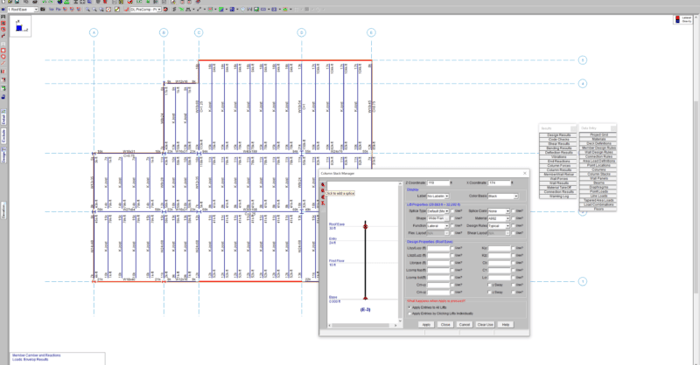

RISAFloor has the ability to model column splices for all columns. You have the choice of a Moment or Shear splice depending upon what type of forces you want the splice to transfer. There are a few different ways to define your splices that give you flexibility in assigning them to your columns.

Our monthly "Structural Moment" newsletter is the best way to keep up with RISA’s product updates, new releases, new features, training events, webinars and more...