Understanding Sign Conventions for Wall Panels & Plates in RISA

While members (beams and columns) follow conventions tied to their local...

RISA software products use different sign conventions depending on the product’s purpose and typical use case. While the conventions are logical within each program, they may appear inconsistent when moving between tools like RISA-3D, RISAFloor, RISAFoundation, and RISAConnection.

This article consolidates the sign convention rules for common forces and moments across these programs, so users have a single reference point for interpretation.

| Program | Positive Moment (M) | Shear (V) Direction | Axial (P) Direction | Display Notes |

|---|---|---|---|---|

| RISA-3D | Top fiber in tension (sagging) → Negative Bottom fiber in tension (hogging) → Positive | Downward on right face = Positive | Tension = Negative | Global/local directions shown in results grids |

| RISAFloor | Top fiber in tension (sagging) → Positive Bottom fiber in tension (hogging) → Negative | Downward on right face = Positive | Tension = Positive | Matches common AISC/textbook convention |

| RISAFoundation | Top fiber in tension (sagging) → Positive | Follows structural sign convention | Tension = Positive | Matches RISAFloor convention |

| RISAConnection | Based on free body diagram convention (force direction matters, not internal sign) | Force arrows into member = Compression Force arrows away = Tension | Force direction shows magnitude/type | Blue arrows clarify direction of loads |

⚠️ Important: The “top fiber” is always the side of the member in the positive local-y direction—not necessarily “up” in the global model.

For beams: this usually coincides with the global upward direction.

For columns: this distinction matters more, since the positive local-y may not be intuitive.

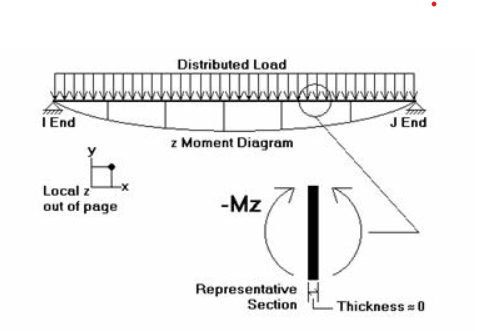

RISA-3D uses a mathematical sign convention consistent with local member axes and internal force equilibrium. This often appears flipped from the structural engineering convention:

Moment (M): A positive moment results in compression in the top fiber, which is typical for cantilevers.

Shear (V): Positive when acting downward on the right side of a cut section (right-hand rule).

Axial (P): Positive = Tension

💡 Tip: This is different from textbook/AISC convention. Keep this in mind when viewing moment diagrams or interpreting internal force reports.

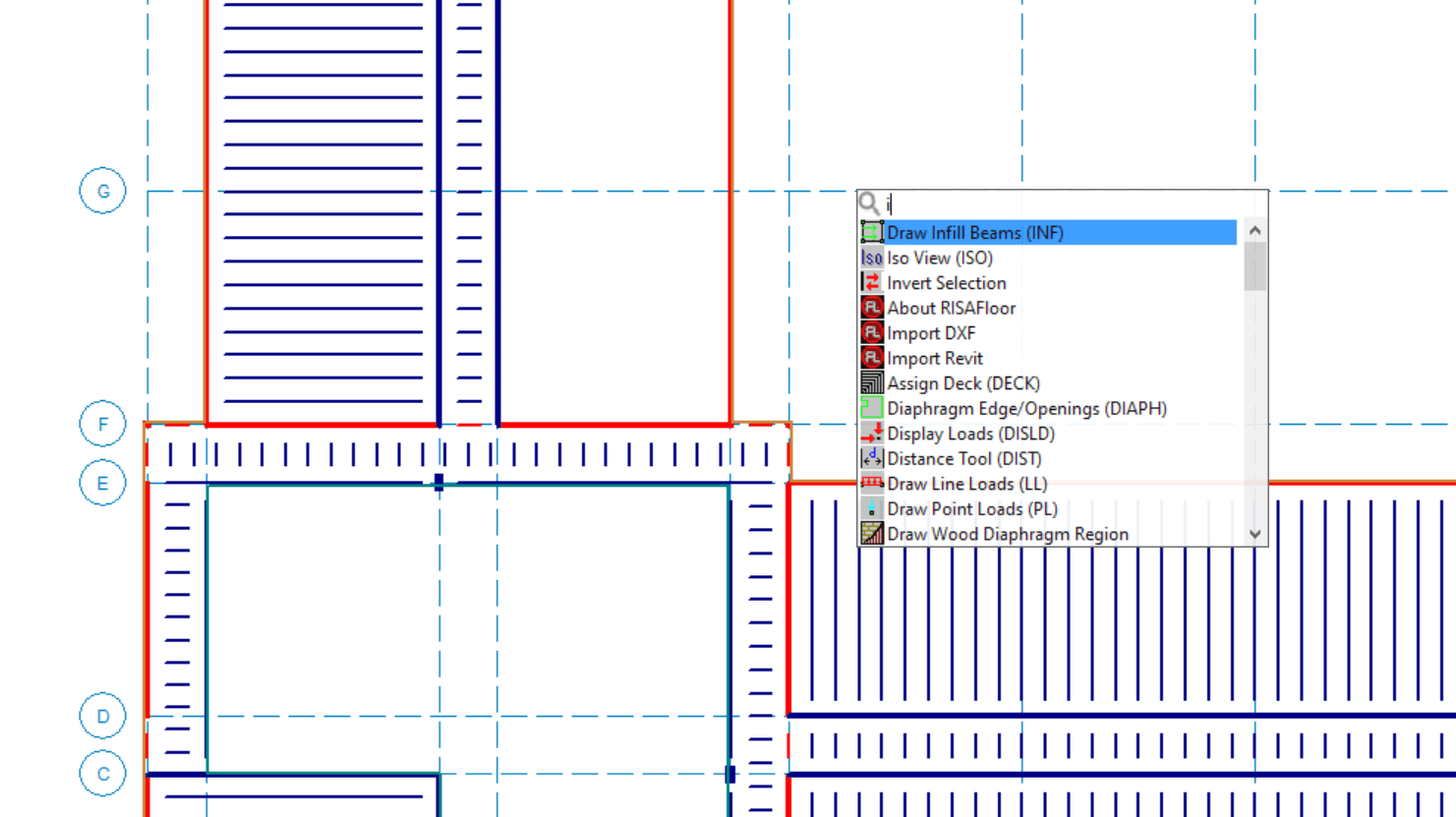

RISAFloor adheres to a more traditional structural engineering convention, common in design references:

Moment (M): A positive moment results in tension in the bottom fiber – i.e., sagging moment.

Shear (V): Same as RISA-3D (downward on the right face is positive).

Axial (P): Positive = Tension

This sign convention aligns with most AISC manuals, textbooks, and hand calculations, making it intuitive for engineers.

RISAFoundation shares RISAFloor’s general approach:

Moment (M): Sagging = Positive (top in compression)

Shear (V): Follows same right-hand rule convention as above

Axial (P): Positive = Tension

In RISAConnection, results are based on the Free Body Diagram (FBD) concept, not internal forces:

Arrows on the 2D connection detail views represent external forces applied to the member.

Blue arrows:

Pointing into the member = Compression

Pointing away from the member = Tension

Moments and shears are shown with directional arrows—interpret these as if drawing a free-body diagram of the member being cut at the joint.

⚠️ Note: Because RISAConnection supports many different connection types (e.g., clip angles, moment connections, base plates), the precise location and direction of forces will vary per module.

Each RISA program is optimized for a specific stage of design:

RISAFloor and RISAFoundation cater to design engineers referencing structural code conventions.

RISA-3D reflects analytical principles that simplify complex 3D modeling.

RISAConnection visualizes external forces at connections, similar to detailing or fabrication shop drawings.

Understanding this context helps reconcile results across the programs.

Looking instead for Sign Conventions for Members in RISA? Read More

Check out our Help File for more info on sign convention in the corresponding products by clicking the links below.

RISAFoundation Sign Convention

While members (beams and columns) follow conventions tied to their local...

New features are now available in the recent release of RISACore...

New features are now available in the recent release of RISACore...