Expanded Load Categories in RISA-3D and RISAFoundation

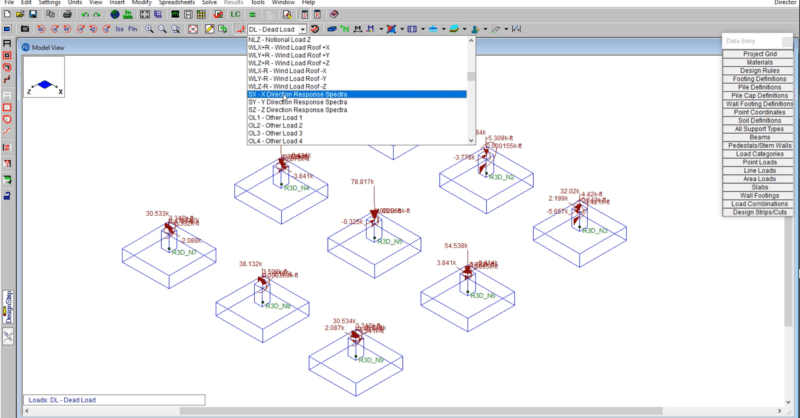

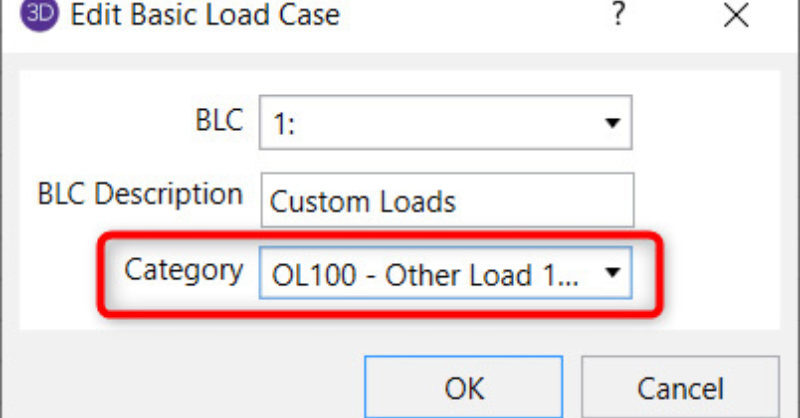

New to RISA-3D v19 and RISAFoundation v13 is the ability to apply up to...

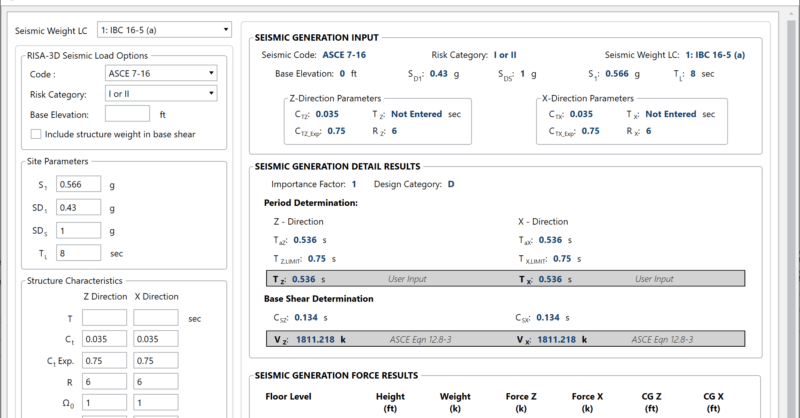

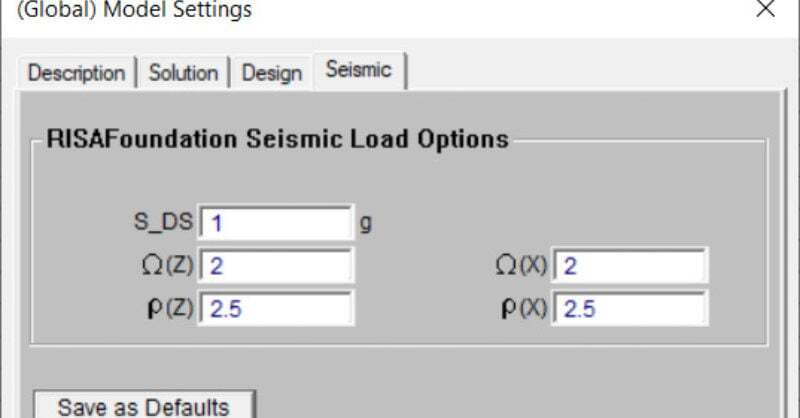

With the release of RISAFoundation v13, you now have the ability to transfer Response Spectra Analysis reactions from RISA-3D v19. RISAFoundation now also includes additional seismic options that can be considered in the generation of Load Combinations.

New to RISA-3D v19 and RISAFoundation v13 is the ability to apply up to...

Seismic Forces are generated automatically using seismic parameters R,...

Seismic factors, including Omega, Rho and Ev, can now be included in...