Troubleshooting Log-In Error for RISACalc

RISACalc is RISA's cloud based structural design software for single...

It was a typical Thursday morning for Emma Ruiz, PE, a structural engineer at a small consulting firm in Colorado. Her day started with a site visit to a rural school renovation—a project where her team was assessing whether a portion of the existing structure could support new rooftop HVAC units.

The original framing plans were incomplete, and as Emma inspected the roof framing, it became clear that the contractor’s proposed unit placement didn’t line up with the assumed beam layout. A decision had to be made, and quickly—the rooftop unit was scheduled for delivery the following day.

Emma didn’t have time to return to the office to rebuild a full model or dig through spreadsheets for older framing checks. She needed to verify—on the spot—whether the existing W10x22 steel beam could support the new loads at the proposed spacing.

The contractor waited, the facilities director asked for reassurance, and Emma pulled out her tablet.

Emma opened RISACalc, selected the beam design template, and input the beam size, span length, and newly calculated roof loads, including snow and equipment live load. In under five minutes, she was reviewing the pass/fail code check results based on the latest version of the AISC Steel Manual.

With visual feedback, moment and shear diagrams, and code references included, she could show the facilities team and contractor what the revised configuration would require—and confirm that the proposed unit location would exceed the capacity of the existing beam.

But instead of rejecting the entire proposal, Emma used RISACalc to test an alternate span arrangement. By moving the unit two feet closer to an adjacent bearing wall and increasing beam spacing to reduce tributary width, the design passed.

That field verification avoided a delay in the construction schedule, prevented a potential rework of the mechanical layout, and gave Emma’s client extra confidence in her recommendations.

Just as important, Emma didn’t need to interrupt her day or assign junior staff to recreate a model in RISA-3D or a spreadsheet when a lightweight, cloud-based solution was available.

RISACalc isn’t designed to replace full analysis software. Instead, it complements your workflow—especially when you’re in the field or dealing with small-scale, fast-moving decisions. In Emma’s case, it allowed her to:

Validate structural behavior in real time

Test multiple load configurations and member sizes

Communicate engineering reasoning clearly to non-technical stakeholders

Keep the project moving without sacrificing safety or standards

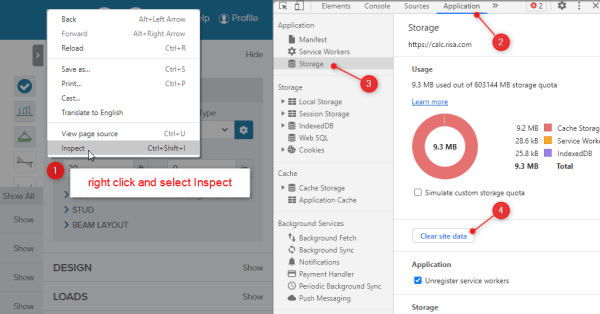

RISACalc is RISA's cloud based structural design software for single...

Meet Tim Barton, one of RISA's go-to problem solvers and Solutions...

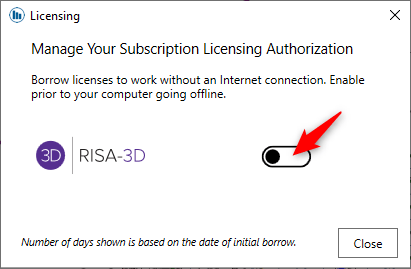

RISA software products allow users to borrow a subscription licenses for...