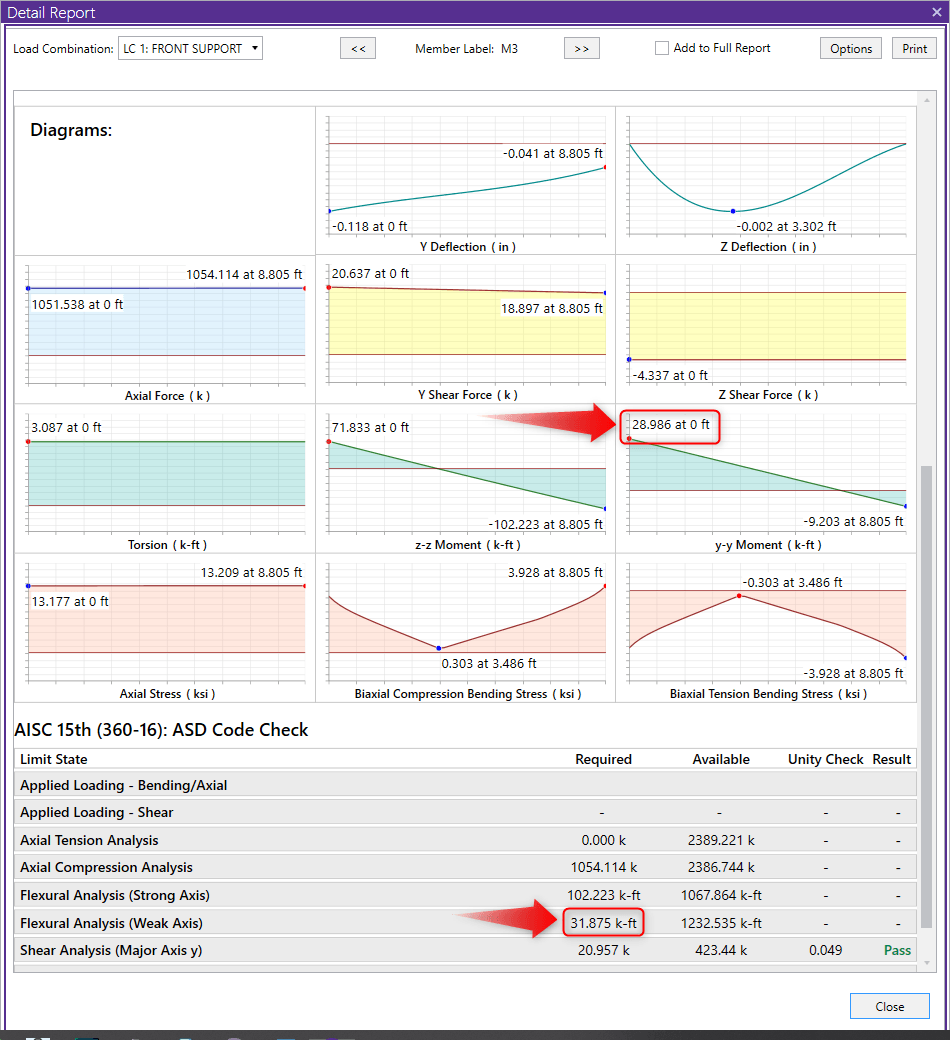

A question that we are asked from time to time in technical support is “why is my required force higher than what is reported in my force diagrams”. For instance, in the detail report below we can see that the maximum moment about the member’s weak axis is 28.9 k-ft. However, the required weak axis moment is reported as 31.8 k-ft.

The reason there is a discrepancy between these two values is that the force diagram is solely reporting the moment about the weak axis whereas the required force is also including contribution from the torsional warping stresses. The required shear force shows a similar difference in that torsion is also included.

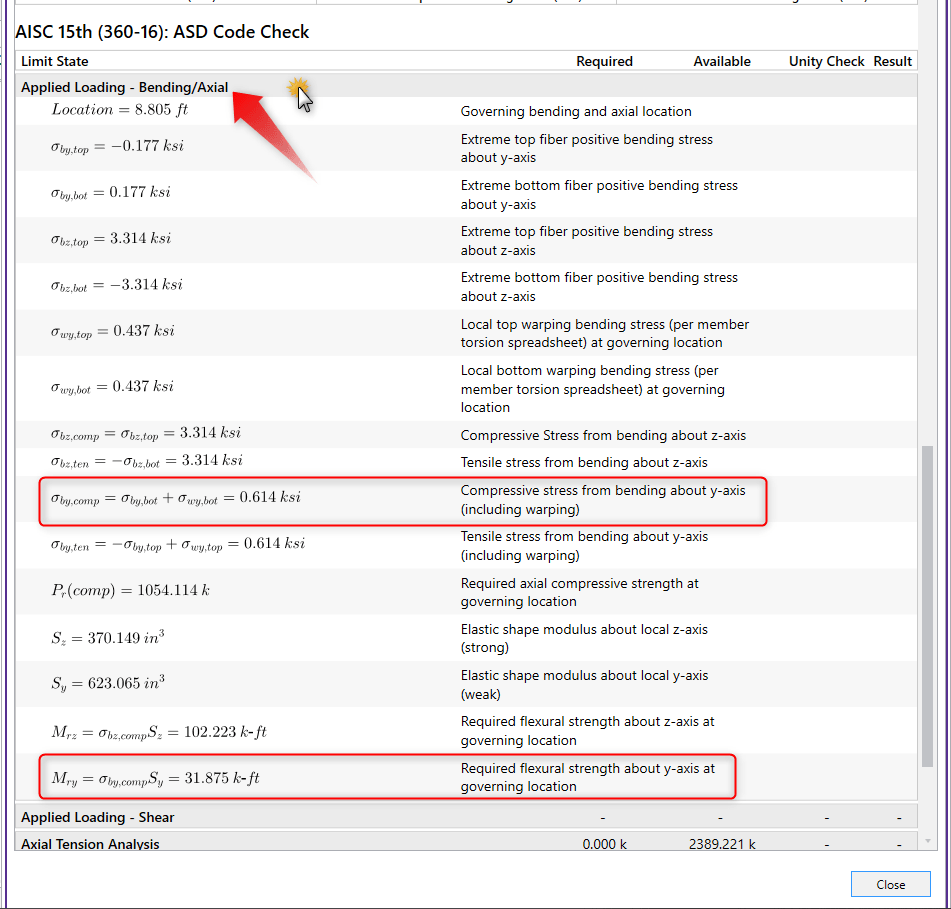

If you are using RISA-3D v18 and newer, you are able to access the new detailed reports which include the full limit state calculation that was used to determine the required forces. In this example, click on the “Applied Loading - Bending/Axial” or “Applied Loading - Shear” section for a breakdown of these calculations.

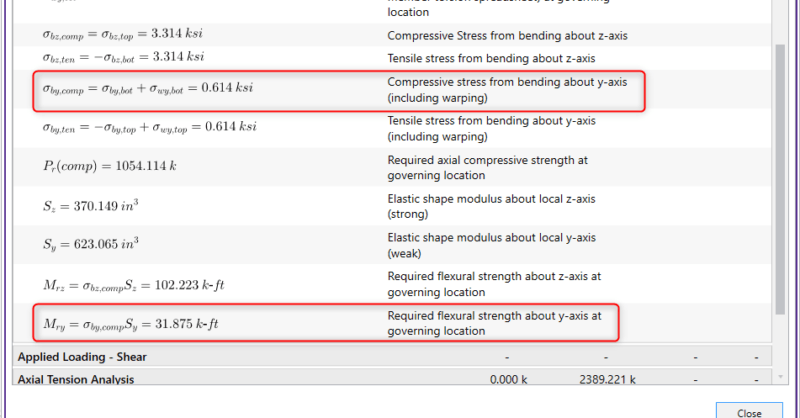

After expanding the “Applied Loading - Bending/Axial” section it becomes clear that required flexural strength is derived from both the weak axis bending stress and the local warping bending stress.

For more information on how the expandable detailed reports can help you understand exactly how the program is deriving its calculations, check out the video below:

You may also be interested in

How Can I Optimize My Members in RISA-3D?

In RISA-3D when drawing members you must start with initial sizes....

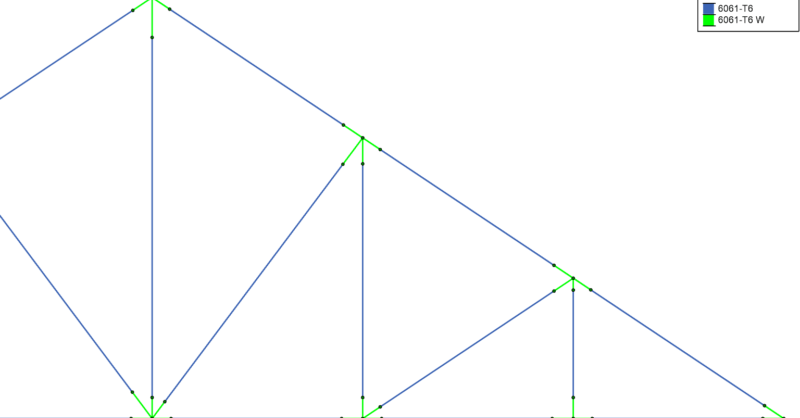

How Do I Consider Welded Aluminum Connections in RISA-3D?

In Aluminum design, the welded areas have a decreased material strength...