New Updates to Steel Joists in RISAFloor

As a floor-by-floor design software, RISAFloor includes robust features...

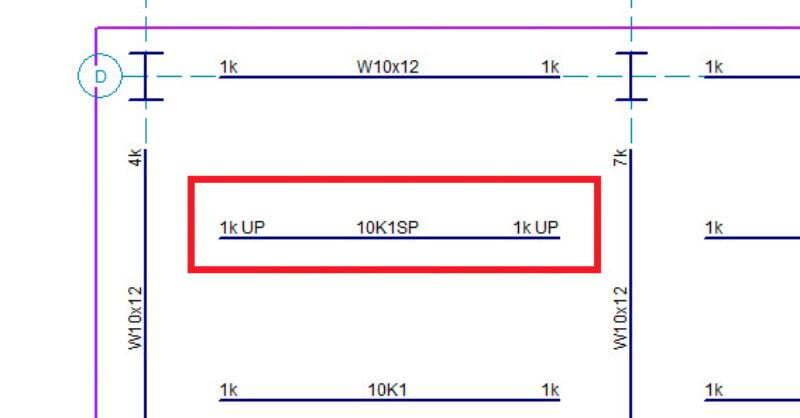

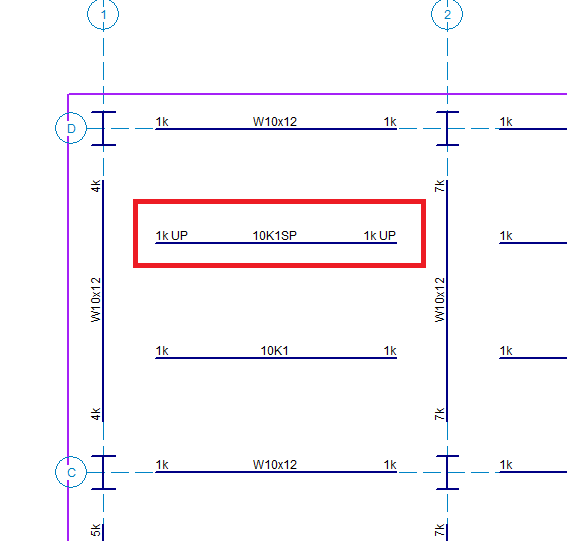

Have you been in RISAFloor performing a steel product design and noticed an (SP) extension to a joist designation? The following will discuss when the program designs for these special loading conditions.

Steel products are designed to resist a uniform dead load (UDL), a uniform live load (ULL), and a uniform total load (UTL). The allowable loads for steel joist are based on the standard load and span tables for K, LH, DHL, and SLH Steel Joists.

However, if a concentrated point load (even one with a small magnitude) is detected on a standard joist, the joist will be flagged as a Special (SP) Joist. Similarly, the distributed load on the joist cannot vary by more than 5% along the length of the joist. If it does then the joist will also be flagged as a SP Joist. The exception to this is some additional load variation is allowed within 10% of the end of the joist.

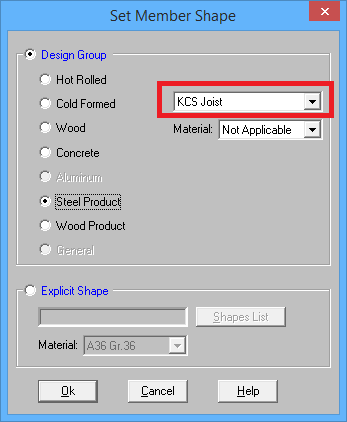

A KCS joist can be designated for these special loading conditions. These joists do not have the “SP” label but are considered a special loading joist. KCS joists are checked versus the constant shear and moment capacity. RISAFloor also ensures the largest applied point load is less than the shear capacity and the sum of the distributed loads at a location are less than 550 plf maximum for K series joists.

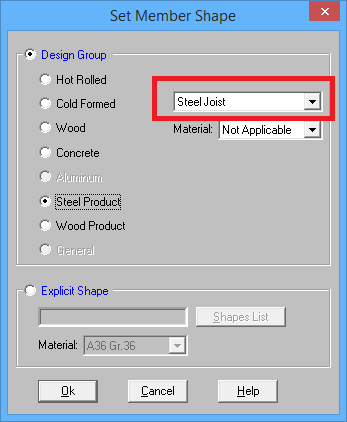

When a general “Steel Joist” is selected in the program, the program will add the SP extension to the joist name to indicate that it is resisting a non-standard load. RISAFloor will choose a joist such that the capacity shear envelope of the joist under a standard uniform load is still greater than the actual shear at all locations along the length of the joist.

In addition to checking the shear envelope, the program will make sure that the maximum allowable moment is not exceeded at one point along the length of the SP joist. The maximum moment is defined as wL2/8, where w is the maximum allowable uniform load for that joist and span that is listed in the joist tables.

As a floor-by-floor design software, RISAFloor includes robust features...

RISAFloor has the capability to design wood I-Joists based on tables...

RISAFloor now includes the ability for engineers to model with and...