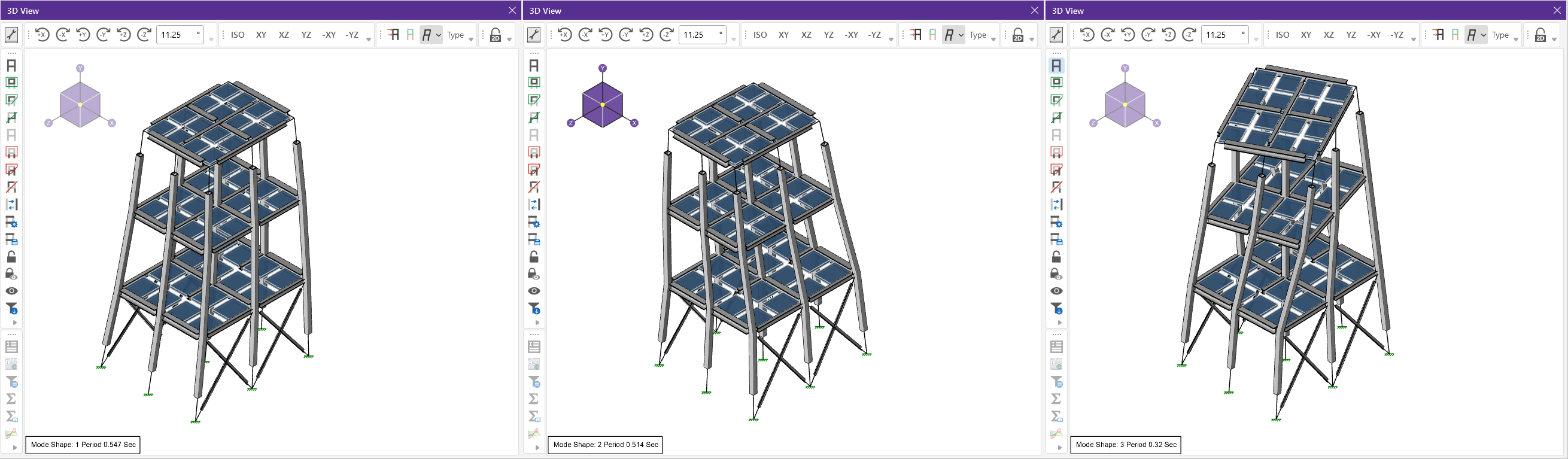

How to Run a Basic Dynamic Eigensolution in RISA-3D?

Welcome to a high-level walkthrough of dynamic analysis in RISA-3D! This...

When a Midwest engineering firm was tasked with designing a 120,000-square-foot manufacturing facility, they knew the challenge wasn’t just about steel and concrete—it was about integration. The structure needed to support overhead cranes, custom conveyor systems, rooftop equipment, and a range of vibration-sensitive machinery. On top of that, the site’s soil profile required deep foundations and a mat slab in high-load zones.

Instead of managing this complex design puzzle across multiple platforms, the firm turned to the full RISA Suite—using RISA-3D, RISAFloor, and RISAFoundation in tandem. The result? A seamless, accurate, and time-saving design process that allowed the firm to deliver ahead of schedule.

With RISA-3D, the team quickly modeled the facility’s steel framing system, including built-up columns, multi-bay trusses, and lateral bracing. Loads from the cranes, roof units, and custom mezzanines were easily applied using RISA’s versatile load generator and load combination tools.

Key wins:

Modeled the entire lateral and gravity system in a single file

Ran multiple load scenarios including seismic, crane surge, and equipment-induced vibration

Used RISA’s code checks to validate steel member sizing under heavy, variable loads

With steel framing locked in, the team launched RISAFloor to handle the facility’s mezzanine levels and elevated slab areas. Since RISA-3D and RISAFloor share the same model, there was no need to re-enter data or recreate the geometry.

RISAFloor allowed engineers to:

Design custom composite floor systems for high-load areas

Automatically calculate tributary loads to supporting beams and girders

Create diaphragm stiffness models for seismic and wind load transfer

The complexity didn’t stop above grade. Certain equipment loads exceeded 100 kips, and the site’s poor soil conditions demanded deep foundations. The team used RISAFoundation to develop a hybrid solution combining mat slabs with drilled piers, all within the same integrated model.

With soil data imported and reactions from the superstructure applied directly from RISAFloor and RISA-3D, engineers:

Optimized pier locations based on actual column loads

Modeled and designed custom mat slabs with variable thickness

Evaluated bearing pressures, punching shear, and settlement—all in one place

The RISA-integrated workflow didn’t just save time—it gave the team confidence. They cut coordination errors by 40%, reduced turnaround time for revisions, and presented a fully coordinated model to the contractor that helped avoid costly rework in the field.

As one lead engineer on the project put it: "Using RISA across the board allowed us to spend more time engineering and less time babysitting disconnected models. We were able to go from concept to construction documents faster than ever before."

Welcome to a high-level walkthrough of dynamic analysis in RISA-3D! This...

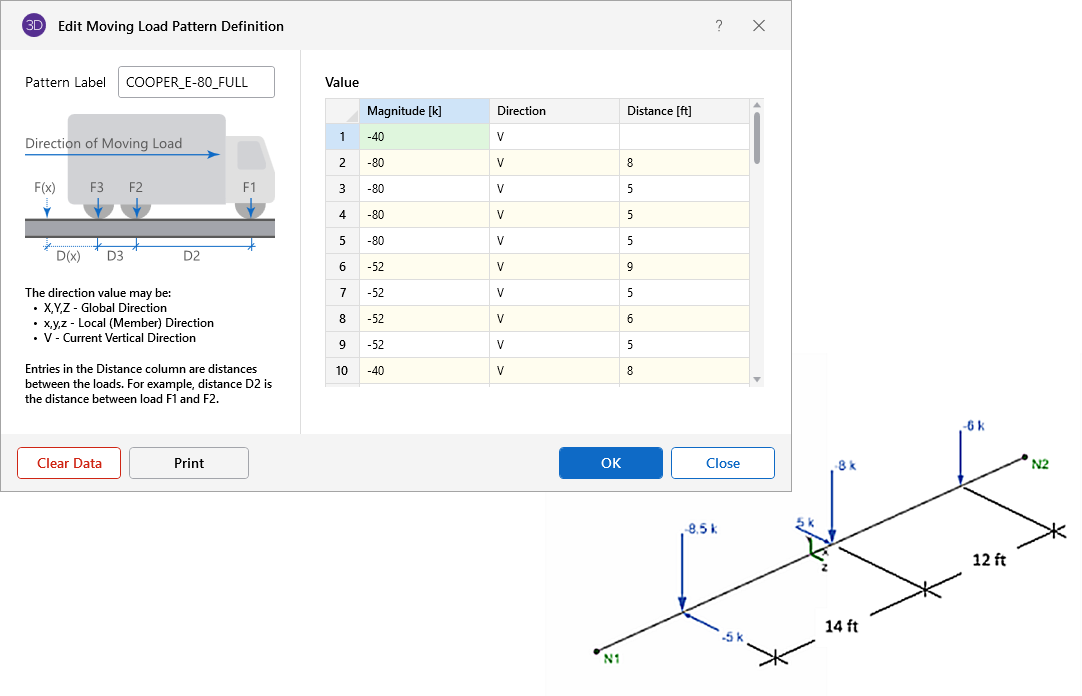

In RISA-3D, moving load results are generated by simulating a load that...