Engineering Tomorrow: The Evolution of Telecom Structure Design

You've probably noticed those cell phone towers around town—those tall...

Industrial steel structures—such as pipe racks, material handling systems, transfer structures, and equipment supports—present a distinct set of challenges compared to conventional building design. These systems are often governed by heavy equipment loads, irregular geometry, non-building load combinations, and serviceability or constructability constraints that demand careful analytical judgment.

Unlike repetitive floor-framed buildings, industrial structures tend to be highly bespoke. Each project requires deliberate decisions around idealization, load application, boundary conditions, and analysis method to ensure the model reflects real structural behavior.

Industrial structures are governed by:

If wind pressure varies around complex geometry, projected plate loads (PX, PY) allow RISA-3D to calculate realistic force reduction automatically — something that would be painful to do by hand.

Booms, cantilevered conveyors, bucket wheels, and offset equipment introduce torsion long before flexure governs.

If torsion matters and the model doesn’t show it, the model is lying to you.

Plates are not overkill in industrial steel — they’re often the only way to see stress flow caused by rotating or eccentric equipment.

Industrial structures routinely include:

If RISA-3D flags instability or convergence issues:

For cable modeling:

No real member is perfectly tension-only — but RISA-3D gives you visibility into when that assumption breaks.

Industrial models often “solve” even when:

Industrial structures evolve:

RISA-3D supports this reality by allowing:

The goal isn’t a single “final” run — it’s a model that remains transparent and defensible as assumptions change.

You've probably noticed those cell phone towers around town—those tall...

On January 24th, we celebrate the International Day of Education, a...

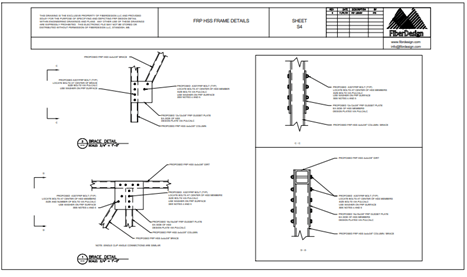

Overview FRP or Fiber Reinforced Polymer (thermoset) composite...