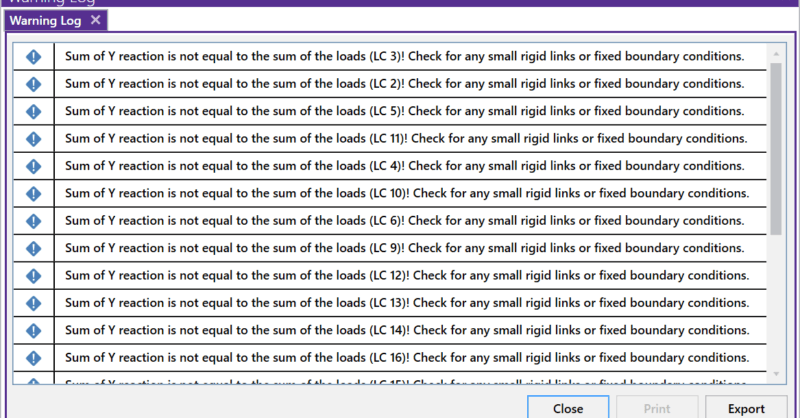

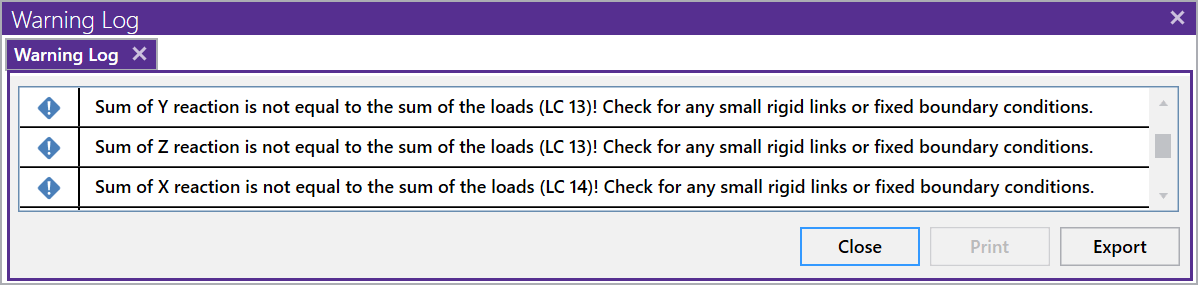

RISA-3D will now check your model for errors by summing the reactions in your model and comparing them to the applied loads. This occurs for the global X, Y, and Z directions. If RISA identifies that the reactions do not equal the applied loads then the software will show a warning message to the user.

There are three main reasons why this might happen:

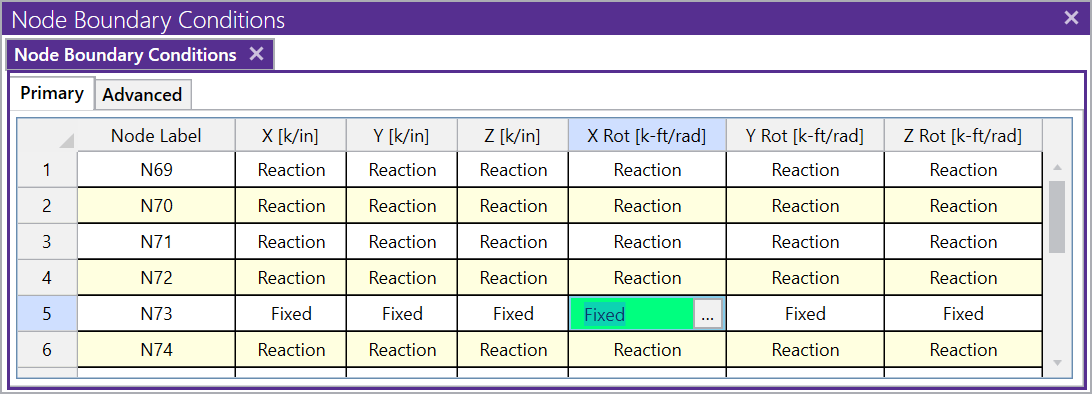

- You have used a Fixed call out in the Boundary Conditions spreadsheet:

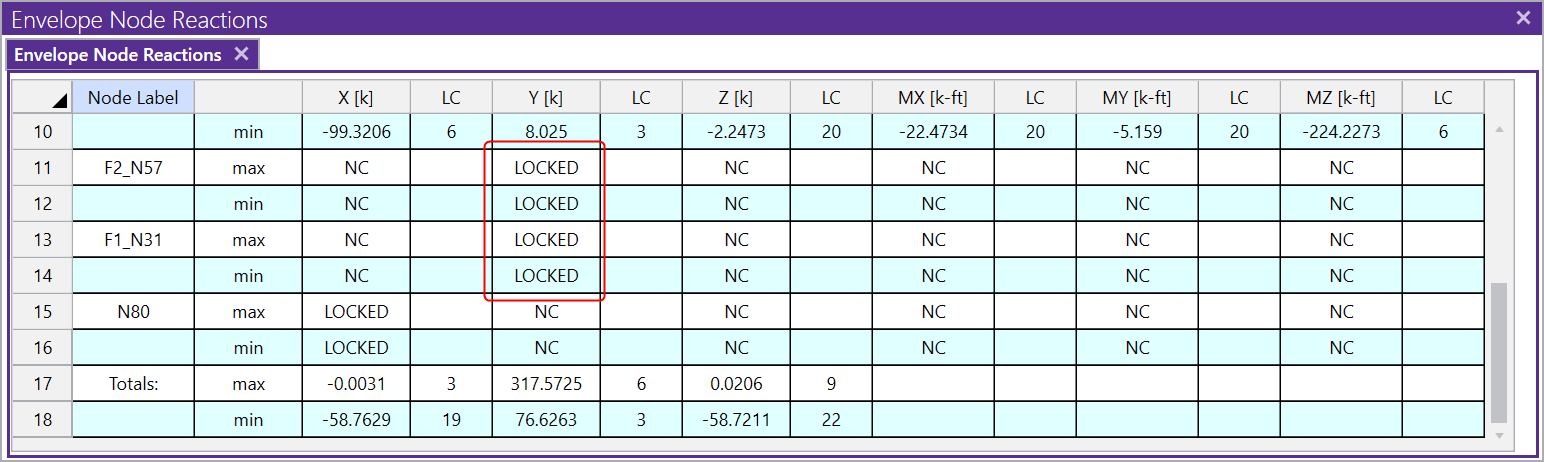

- There are instabilities in your model, causing locked joints:

These locked joints may have an actual reaction coming out, but because the program was forced to lock it there is no calculation of this reaction. Fix the instabilities and the message will likely go away.

- Areas of high rigidity simulating boundary conditions (sometimes referred to as ghost reactions):

If you have an area of your model that has a concentrated amount of very stiff elements and/or single elements that have very high stiffness, then these areas may approach the stiffness of a boundary condition and erroneously take load out of your model.

Common reasons why this might happen:

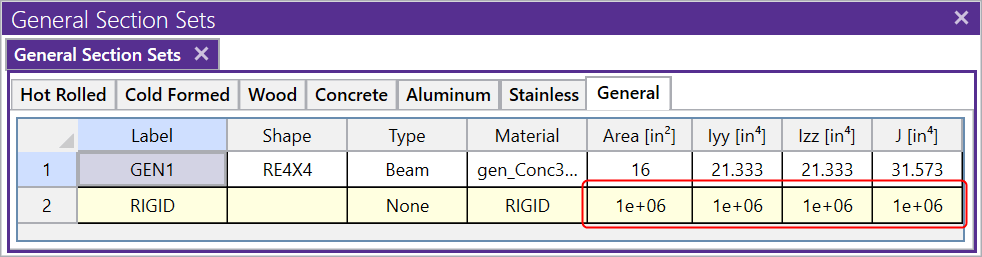

- Setting the E and I values for your Material or Section Set overly high. A rule of thumb is to not set these values greater than 1 e+6.

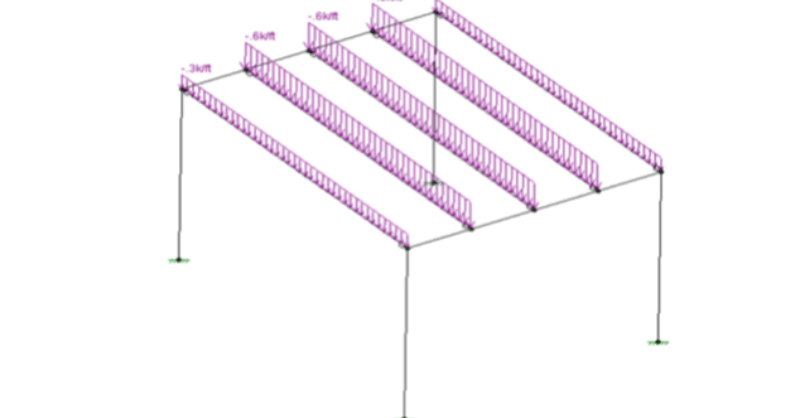

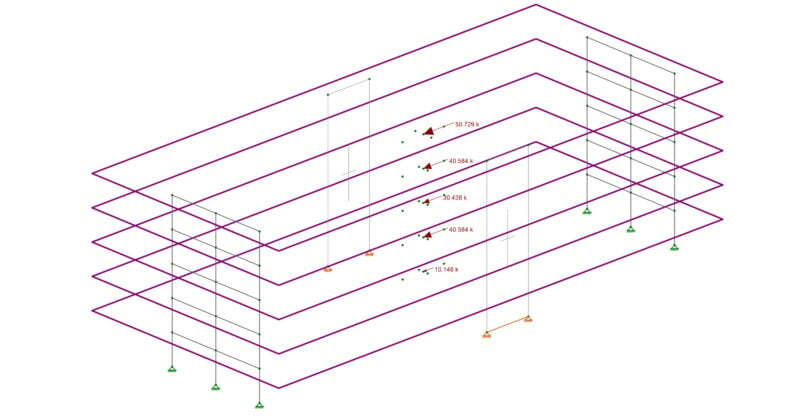

- Using diaphragms in combination with a large amount of rigid links or the top of member tool.

- Connecting many very rigid members/elements together at one location.

You can fix these issues by reducing the stiffness of the elements causing the problem or by eliminating some of these elements that may not be necessary.

You may also be interested in

Refining Area Load Distribution in RISA-3D

After solving a model with Member Area Loads, RISA-3D will...

How To Generate Seismic Loads Automatically in RISA-3D

Applying seismic loads to structures with rigid diaphragms can be done...