How Do I Model a Tapered Pipe?

Tapered members are common for metal buildings and pole-type...

RISA has now incorporated the tapered member design provisions from Steel Design Guide 25: Frame Design Using Web-Tapered Members written by Richard Kaehler, Don White and Yoon Kuk Kim. These code checking procedures are used whenever the AISC 13th or 14th edition steel codes are selected.

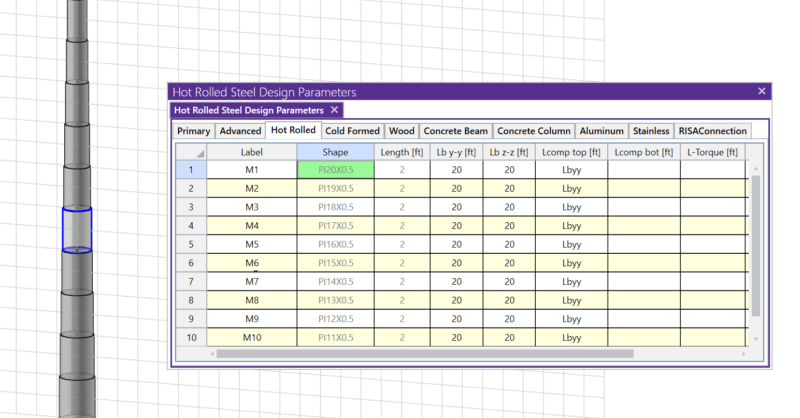

No special modeling is required inside of RISA-3D. Just create the tapered members, assign design parameters and designate the AISC 13th or 14th edition as the design code, then RISA-3D will give you analysis and design results for your frame.

Older versions of the AISC code (ASD 9th and LRFD 3rd) used to have specifications in Appendix F detailing how to perform member design of web tapered members. RISA incorporated these design provisions directly into the program’s code checking procedures.

With the 2005 release of the unified AISC 13th edition steel specification, AISC removed all design provisions for these types of web tapered members. Between the publication of the 13th edition steel code and the publication of Design Guide 25, RISA (and the design community as a whole) lacked clear guidance over how these members should be designed. Therefore, versions of RISA-3D prior to version 11.0 were unable to perform code checks for tapered members when using the AISC 13th or 14th edition steel codes.

The older AISC Appendix F design provisions were somewhat limited and may not have reflected the types of tapered members that engineers really wanted to use in design of these frames. In particular, the old provisions required that the flanges be of equal and constant area. Since this is not required with the new provisions, that opens up RISA analysis to a much wider range of tapered frames.

The old provisions were very much dependent on the calculation of an equivalent effective length for determining the stability of the frame. Since the current AISC provisions are more geared towards the Direct Analysis Method’s stability calculations, the provisions in the design guide are much more compatible with the current steel specifications.

The design guide and the newer AISC specifications will check some failure modes that the older codes did not. These include Torsional Buckling, Flexural Torsional Buckling, and Constrained Axis Torsional Buckling

RISA has traditionally provided information about the maximum code check in the member’s detail report. Information such as the code check location, the controlling combined force equation, as well as the moment and flexural capacities used in that equation.

However, the detail reports for tapered members now give a good amount more information as shown below. A governing equation is now given for each Axial, Moment or Shear capacity reported. In addition, the slenderness limits and parameters used in the capacity calculation are reported as well.

Lastly, in addition to the governing code check equation, the program will report the failure state of that equation. For example, in the above image equation E7-2 could correspond to strong axis (z-z) or weak axis (y-y) buckling. Similarly, the strong axis moment capacity could be dictated by Flange Local Buckling (FLB), or Lateral Torsional Buckling (LTB).

For more detailed information on tapered member design, please see the RISA-3D help section on "Tapered Members".

Tapered members are common for metal buildings and pole-type...

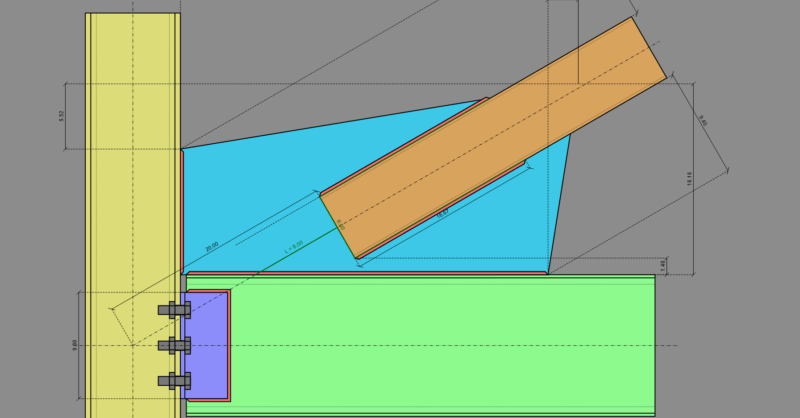

In RISAConnection v8, you may now design a Knee Brace and Diagonal...

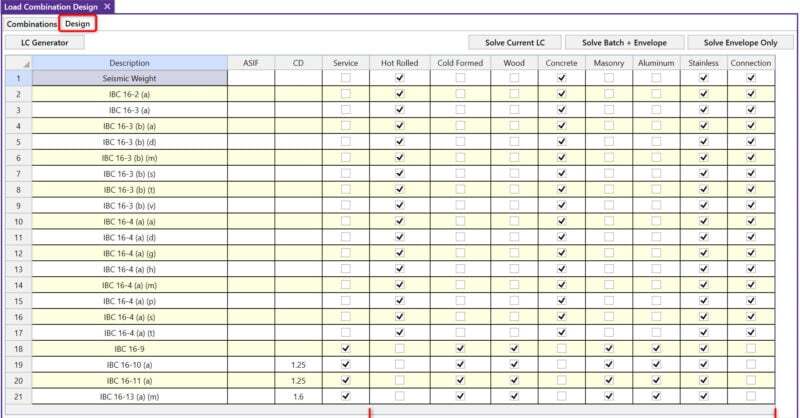

RISA-3D includes material specific checkboxes on the Design tab of the...