Video: Mat Slab Design in RISAFoundation

In this video, we’ll take a look at the modeling and analysis of a mat...

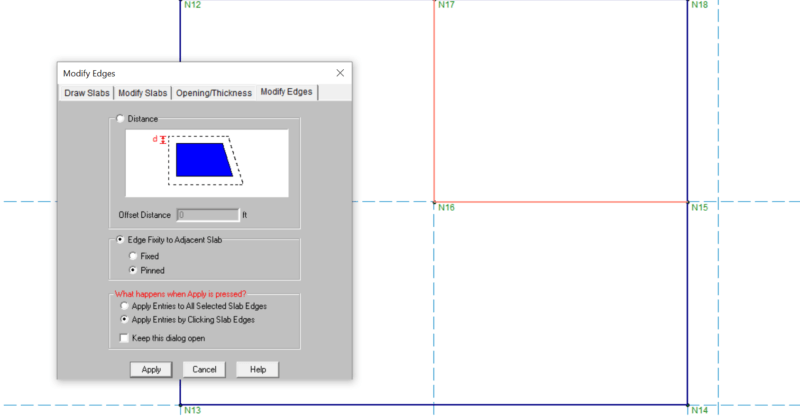

In RISAFoundation v8, you can add a shear splice between slabs so that it acts like a hinge. This is useful for modeling the effects of shear keys or dowel joints between slabs.

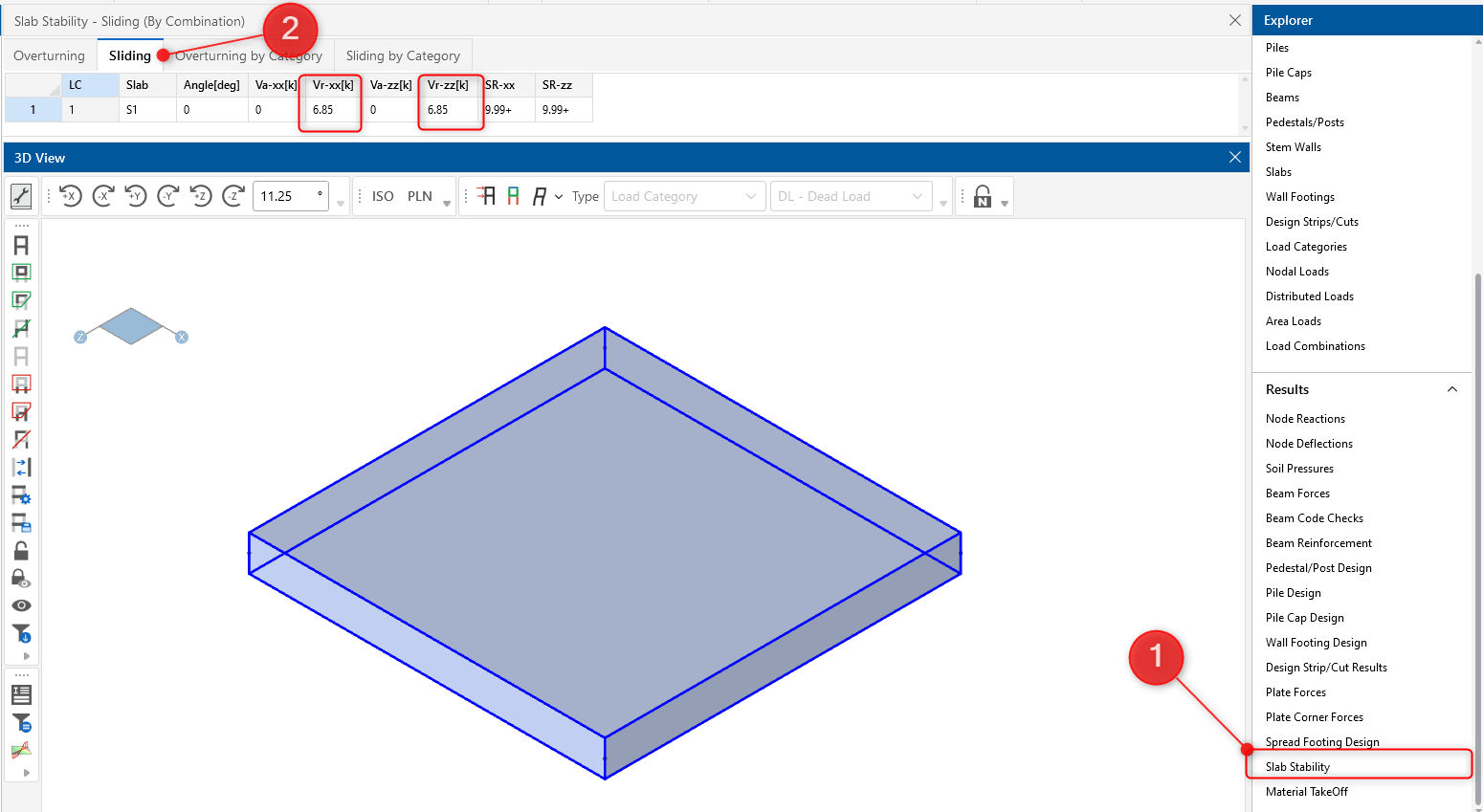

In this video, we’ll take a look at the modeling and analysis of a mat...

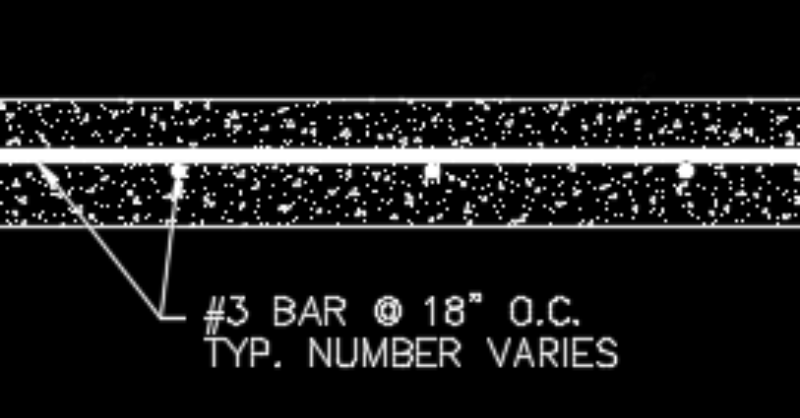

RISAFoundation has the ability to create a single layer of...

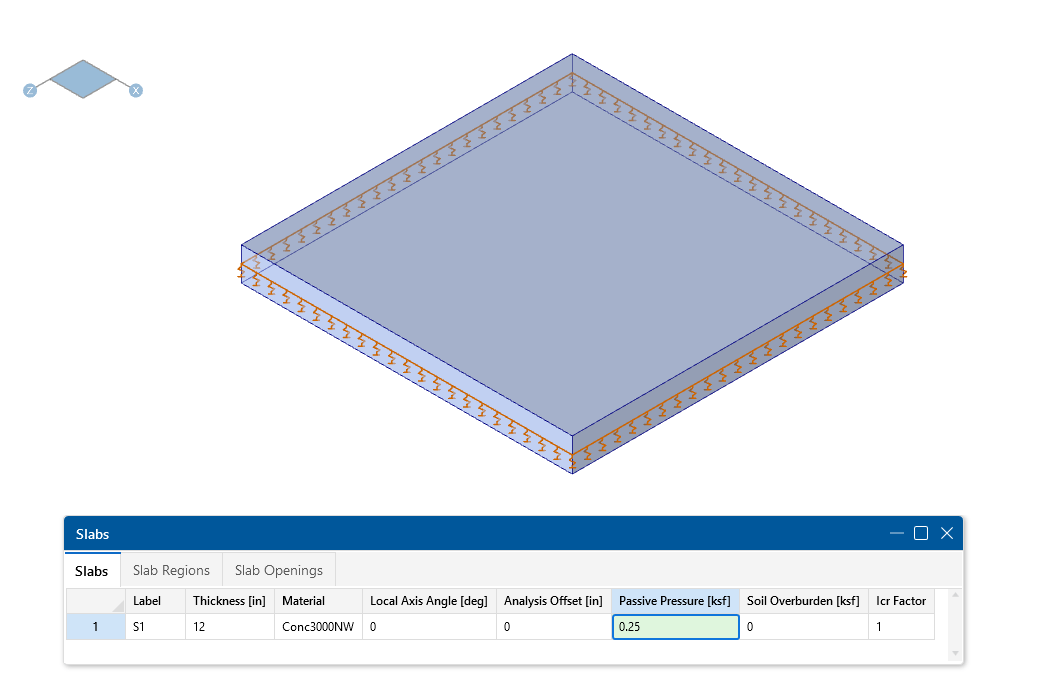

RISAFoundation includes the added ability to enter a passive pressure...