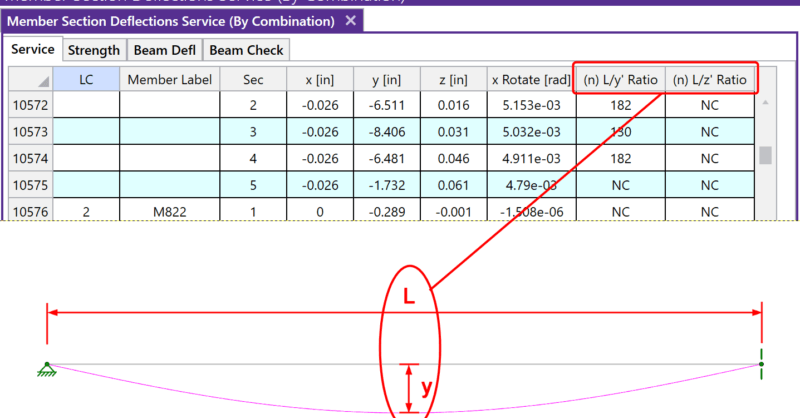

Beam Deflection Ratio Options

RISA-3D v16.0.4 introduces an enhancement that will allow for more...

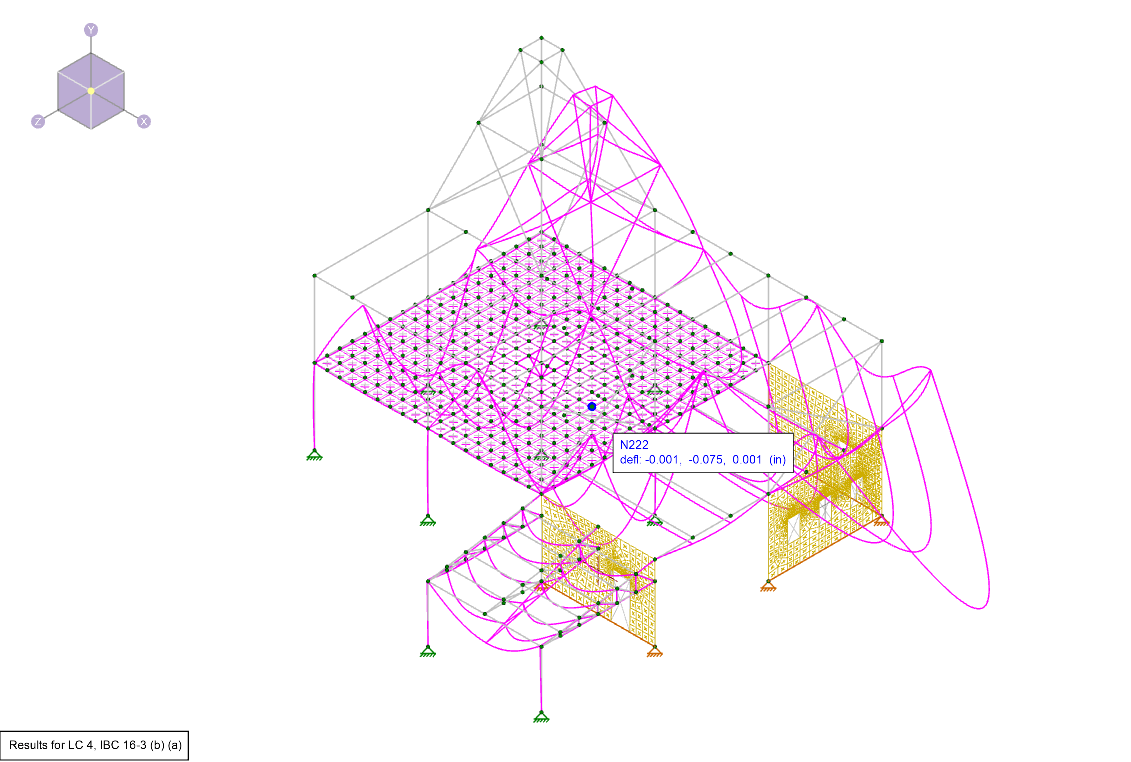

Deflection is a key tool for verifying whether your model was built correctly in RISA-3D. After solving, you can view the deflected shape to confirm if the deflections are within the expected range. If you notice abnormal deflections, use the following steps to troubleshoot the issue.

-2.png?width=450&height=233&name=image%20(44)-2.png)

Steps for Investigating Large Deflections

Additional Resources

If you're designing with steel members and still noticing deflections greater than those predicted by traditional beam equations, check out the aricle linked below.

Have more questions about deflections in RISA-3D? Contact our support team or explore our Help File for further assistance.

RISA-3D v16.0.4 introduces an enhancement that will allow for more...

.png)

RISAFloor ES allows users to analyze Long Term Deflection for Concrete...

After solving a model, you will see in the Member Deflections...