WEBINAR: Design of Cold-Formed Steel Buildings in RISA

More and more, commercial buildings are being designed as...

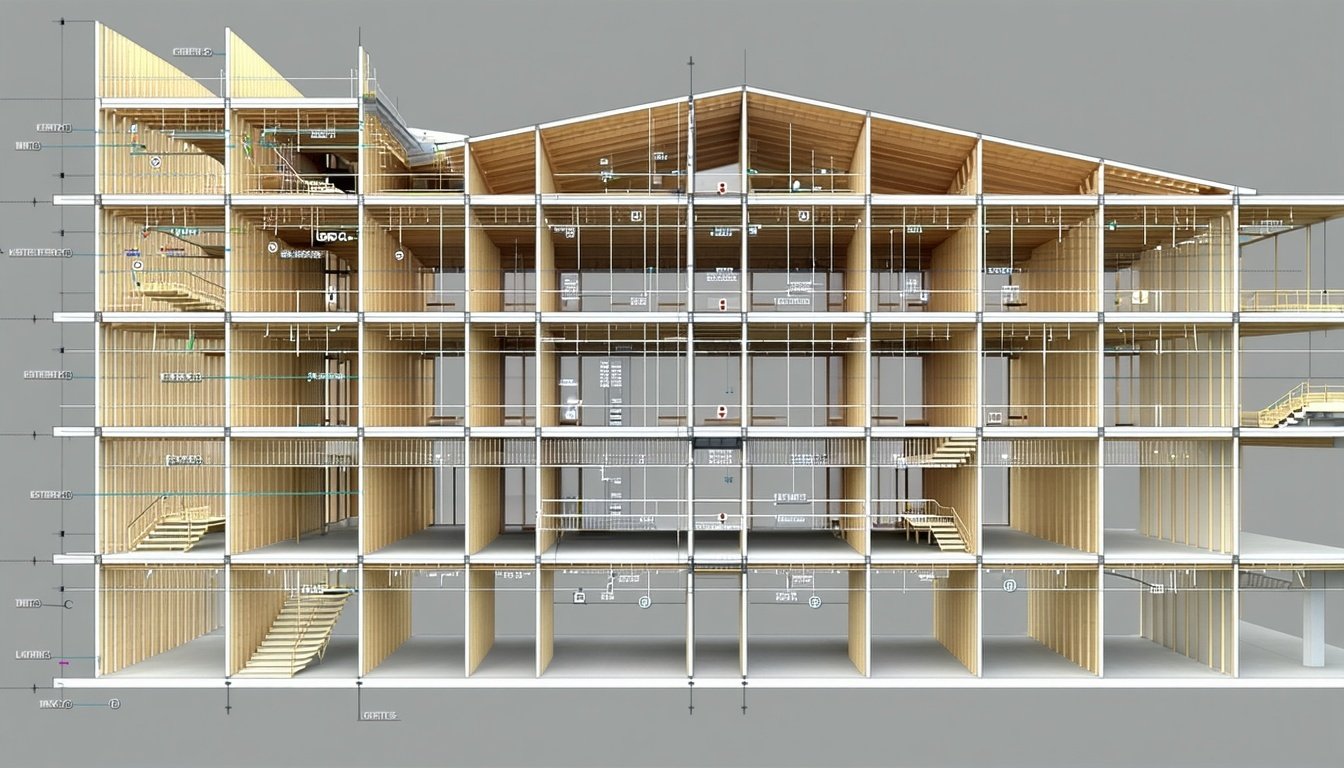

Light-framed construction has become increasingly prevalent in mid-rise and modular development, driven by its cost-efficiency, speed of construction, and adaptability. But with flexibility comes complexity. Engineers designing with wood and cold-formed steel (CFS) must navigate a unique set of challenges: diaphragm behavior, segmented shear walls, buckling sensitivity, and code-specific checks that differ from traditional hot-rolled steel or reinforced concrete structures.

This article explores practical modeling and design approaches for light-framed buildings, focusing on how structural engineers can balance constructability, analysis clarity, and compliance with governing codes.

In light-framed buildings, flexible diaphragms are often assumed due to the nature of wood sheathing or light-gauge decking. However, as buildings increase in size and irregularity, this assumption deserves scrutiny.

Flexible diaphragm assumptions work well in rectangular buildings with regular framing, but irregular load paths or large openings may require semi-rigid modeling to capture torsional behavior.

Engineers should consider the influence of diaphragm stiffness when assigning lateral forces, especially in hybrid systems where part of the structure may be stiffer or tied into concrete cores.

In projects where semi-rigid diaphragm analysis was warranted, integrating tools like finite element meshing helped visualize how in-plane stiffness impacted overall response—particularly in designs with cantilevered corridors or discontinuous walls.

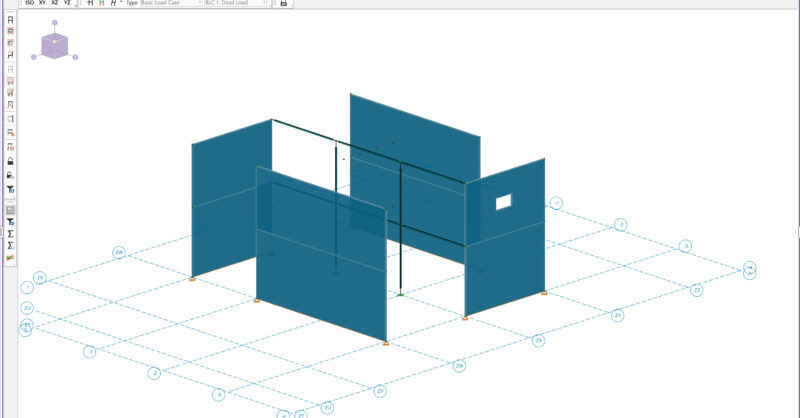

Both wood and CFS rely heavily on shear walls for lateral resistance. Proper modeling of wall segments—and the connections between them—is critical to achieving accurate results.

For wood structures, individual wall segments should be evaluated for overturning, stiffness, and contribution to lateral force resistance. When discontinuous, collectors and drag struts must be clearly defined.

For CFS, panelized systems require consideration of local buckling, track-to-stud connections, and the influence of sheathing on lateral stiffness.

In one example, a prefabricated CFS facade required separate lateral analysis to isolate diaphragm interaction and torsional response before it could be safely tied into the primary steel frame.

Light-framed buildings are often highly repetitive—joists at 16" or 24" o.c., standard wall heights, modular layouts. However, it’s rarely practical to model each joist or stud.

Tributary load methods are still effective for floor and roof framing.

Simplified framing layouts can be modeled as line elements with modified stiffness, provided serviceability checks are still verified (e.g., deflection limits, vibration criteria).

For longer spans, particularly in wood, creep deflection and time-dependent effects must be considered.

Gravity framing should be coordinated with lateral systems early—especially where wall layouts impact both diaphragm and vertical load tracking.

Unlike steel and concrete design, wood and CFS are governed by material-specific codes with adjustment factors, limit states, and unique failure modes.

NDS (National Design Specification for Wood Construction) requires engineers to apply various modification factors (e.g., duration, moisture, temperature) that affect member strength and stiffness.

AISI-S100 (North American Specification for CFS) includes provisions for distortional buckling, effective width calculation, and local buckling that may not be immediately obvious without software support.

Engineers must ensure that software used for analysis and design applies these code provisions accurately—or be prepared to run supplemental checks manually.

Modern projects often blend materials: wood over podium, CFS facades on steel cores, or combinations of CLT and stick-framing. In these hybrid systems, coordination across structural elements and disciplines becomes critical.

Designers should:

Identify clear lateral and gravity systems early in schematic design.

Establish diaphragm behavior and lateral load paths in coordination with the architect and MEP.

Use tools—whether software or calculation-based—that provide flexibility in assigning materials, code checks, and diaphragm types.

While structural modeling software like RISA or others can help streamline this integration, sound engineering judgment and thoughtful detailing remain central.

Designing light-framed structures is both an art and a science. As material usage evolves and buildings grow in height and complexity, engineers must balance code requirements, real-world behavior, and practical modeling strategies. By thoughtfully addressing diaphragm assumptions, wall segmentation, and system interaction, structural engineers can deliver safe, efficient, and buildable light-framed designs.

More and more, commercial buildings are being designed as...

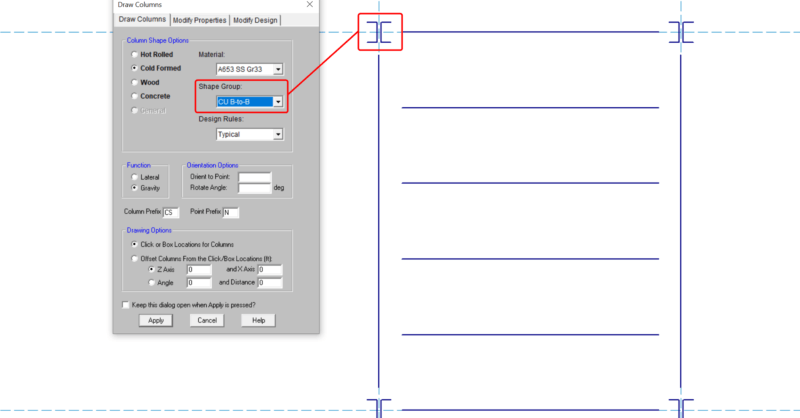

Cold-formed steel framing is a durable, reliable and cost-effective...

In many cases, cold-formed steel channels are built-up as back-to-back...