How to Append or Merge Multiple Models Together in RISA-3D

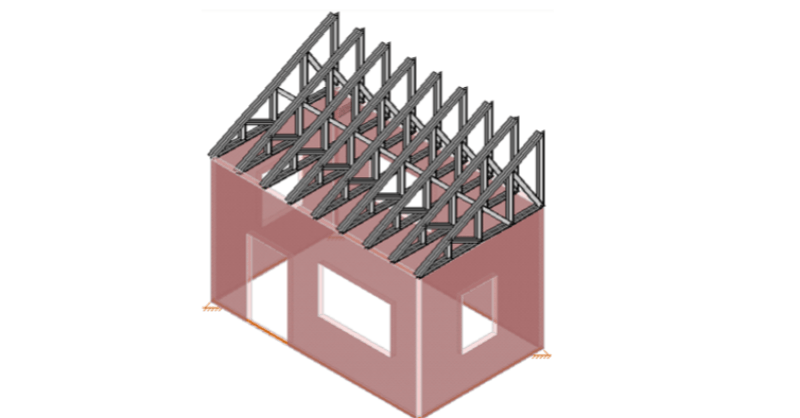

RISA-3D allows you to append, or merge, multiple models into a single...

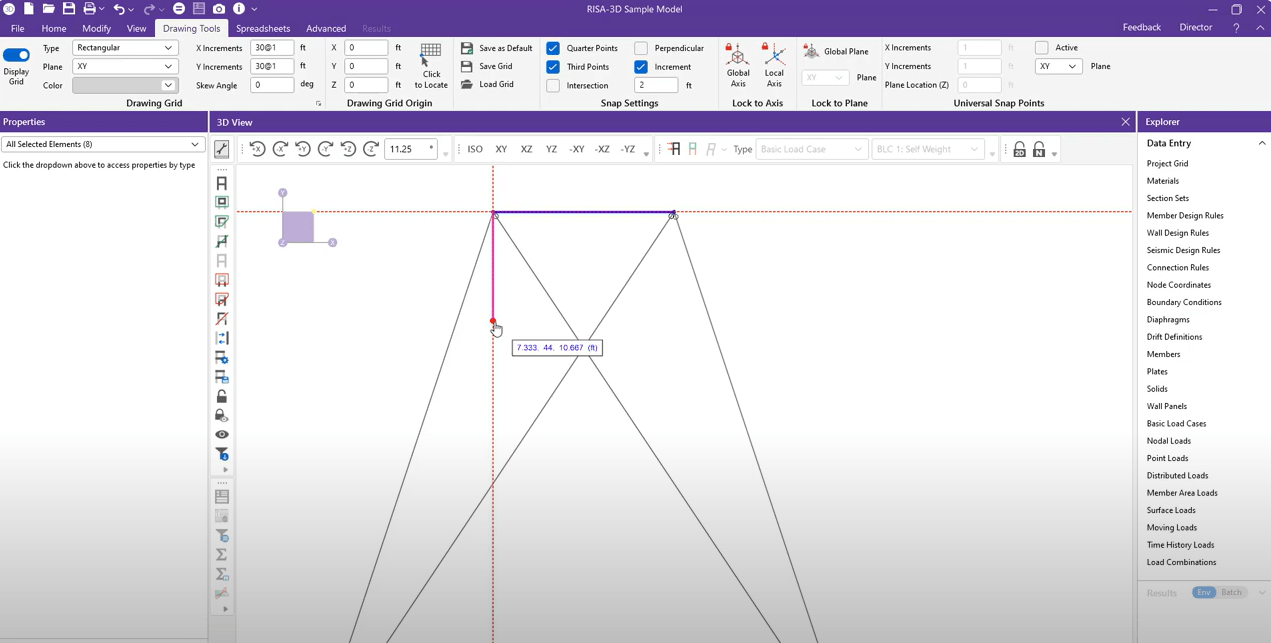

Introducing RISA-3D v22.0, the latest milestone in structural engineering innovation! One of the standout features of this release is the ability to move nodes with a simple mouse gesture in the 3D graphical view. This intuitive functionality revolutionizes your design process, allowing for seamless adjustments and precise control over your structural model. Say goodbye to tedious manual input and hello to effortless manipulation of nodes. Experience the power of RISA-3D v22.0 and take your structural designs to new heights!

RISA-3D allows you to append, or merge, multiple models into a single...

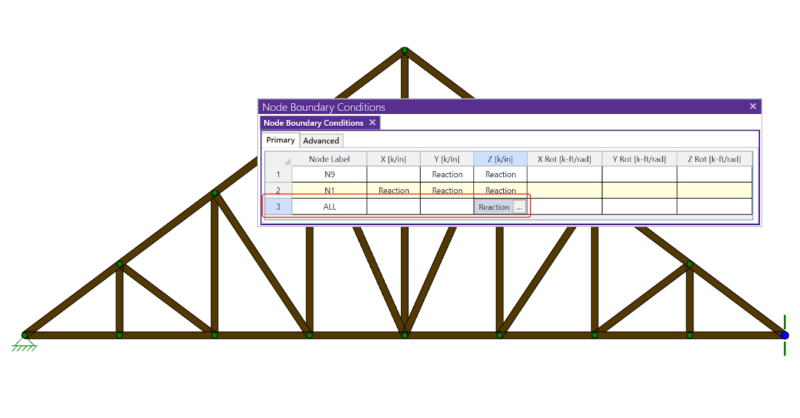

If you have ever tried to solve a two-dimensional model in RISA-3D,...

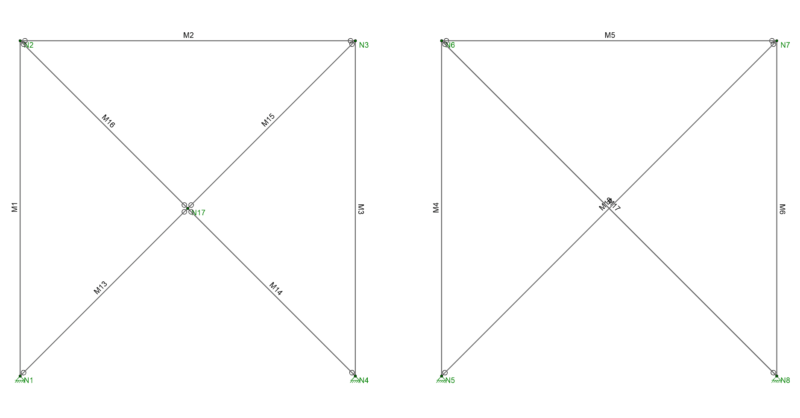

There are several tips to modeling X-Bracing within RISA-3D that can...