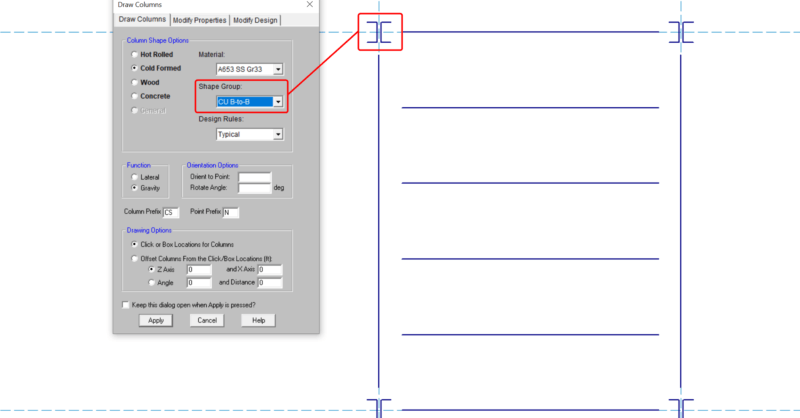

Design of Back-to-Back CFS profiles now in RISAFloor

In many cases, cold-formed steel channels are built-up as back-to-back...

Learn how to load and design individual beam and column cold-formed steel members in RISACalc.

In many cases, cold-formed steel channels are built-up as back-to-back...

More and more, commercial buildings are being designed as...

Learn how to load and design individual beam and column concrete...